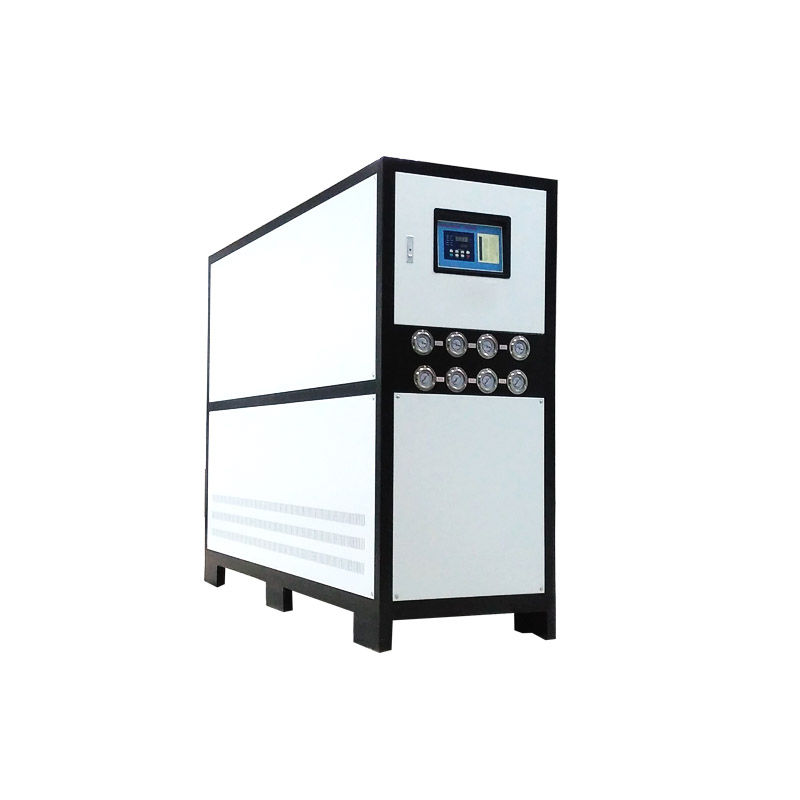

Water-cooled Chiller

A water-cooled chiller is a type of refrigeration system used for cooling applications that utilizes water as the primary cooling medium. It is commonly used in commercial, industrial, and large-scale applications where high cooling capacities are required. Water-cooled chillers are known for their ......

Send Inquiry

Product Description

A water-cooled chiller is a type of refrigeration system used for cooling applications that utilizes water as the primary cooling medium. It is commonly used in commercial, industrial, and large-scale applications where high cooling capacities are required. Water-cooled chillers are known for their efficiency and ability to handle heavy cooling loads.

Here are the key components and working principles of a water-cooled chiller:

1. Compressor: The compressor is responsible for compressing the refrigerant gas, increasing its temperature and pressure.

2. Condenser: In a water-cooled chiller, the high-pressure and high-temperature refrigerant gas is sent to the condenser, which consists of a heat exchanger. Water is circulated through the condenser, absorbing the heat from the refrigerant and causing it to condense into a liquid state.

3. Cooling Tower: The heated water from the condenser is pumped to a cooling tower. The cooling tower uses the process of evaporation to remove heat from the water, reducing its temperature. Air is blown over the water, facilitating the evaporation process and removing heat from the water.

4. Expansion Valve: The high-pressure liquid refrigerant from the condenser passes through an expansion valve or an expansion device. This valve regulates the flow and reduces the pressure of the refrigerant, allowing it to expand rapidly.

5. Evaporator: The low-pressure and low-temperature refrigerant from the expansion valve enters the evaporator. The evaporator absorbs heat from the process or application being cooled. As the refrigerant evaporates, it absorbs heat, thereby cooling the surroundings.

6. Refrigerant: The refrigerant is the working fluid that circulates through the chiller system, undergoing phase changes from gas to liquid and back to gas.

Water-cooled chillers require a constant supply of cooling water to remove heat from the condenser. The cooling tower is responsible for dissipating the heat into the atmosphere through evaporation. The cooled water is then recirculated back to the chiller for the condenser's cooling process to repeat.

Water-cooled chillers offer certain advantages, including higher efficiency compared to air-cooled chillers, higher cooling capacities, and reduced noise levels. However, they require additional equipment, such as cooling towers and water pumps, and typically have higher installation and maintenance costs.

The selection of a water-cooled chiller depends on factors such as the cooling load, ambient conditions, availability of a water source, and energy efficiency requirements. It is important to consult with HVAC professionals or chiller manufacturers to determine the most suitable water-cooled chiller for your specific application.